It didn’t take long after the coronavirus hit the world before medical masks sold out in the United States. I’m not sure if they sold out before the first case arrived in an American hospital, but it wasn’t long after that they did.

People bought up masks as fast as they could, in an effort to protect themselves from the deadly virus.

This wasn’t the first time I saw this happen. It happened during the Ebola outbreak of 2014 as well. Pandemics are scary and so people panic easily. They don’t know what to do, so they do what they can. Part of what they can is to buy surgical masks, thinking that they will protect them from catching the disease.

But what do you do when there are no more masks to buy? The first thing that happens is that people run around buying any other kind of mask they can find, hoping it will be good enough.

So, all the dust masks in all the hardware stores and lumberyards sell out just as fast as the medical masks did.

Then what?

Then there’s nothing else to buy.

If you want a mask, the only thing left is to make one yourself.

Developing the Parameters

The idea behind wearing a medical mask is to catch airborne germs; both bacteria and viruses. But that’s somewhat of a misnomer, as there are very few diseases which are actually airborne.

Rather, those diseases are spread abroad by what is known as “aerosol;” droplets of spittle from coughing and sneezing. These droplets travel a maximum of either six or 12 feet, depending on which medical studies you believe.

In either case, they carry disease-causing germs within themselves, some of which can be breathed in by others, spreading the disease.

The standard medical mask is made of three layers of material, with the outer layer being plastic, so that water could not pass through it. The other two layers are absorbent.

The idea is that the absorbent layers will catch and absorb the spittle from any coughs or sneezes by the medical personnel wearing them, not that they will protect the doctors and nurses from any coughs and sneezes by their patients.

Nevertheless, since the outer layer of these masks is made of waterproof material, they will stop spittle from their patients, even though they won’t absorb it.

So, the masks are an aid in preventing medical personnel from contracting the disease.

The other common mask is the N95 mask that you’ve probably heard of. These masks are a hard cup-shaped mask, with a soft aluminum strip that forms over the nose.

Unlike the standard medical mask, these are intended to protect the wearer, as they filter incoming air. Molding the mask to the nose, with the aluminum strip, helps to ensure that no disease-laden droplets get around the mask and into the nose or mouth of the wearer.

The N95 rating actually means that the mask is expected to stop 95% of particulate matter; in other words, dust. However, because the outer layer of this mask is absorbent paper, it will also catch droplets of spittle.

So, whatever we come up with must be able to both filter our particulates and absorb spittle. The mask must also seal around the nose and mouth, preventing any stray droplets from getting around the edges and contaminating us.

Here’s what I came up with.

The Homemade Pandemic Mask

I wanted to limit myself to materials that would be readily available, even in the midst of a pandemic. I’m assuming that people can get to the grocery store and the hardware store, even though doing so is a risk.

But the materials must be readily available so that people don’t really have to hunt for them.

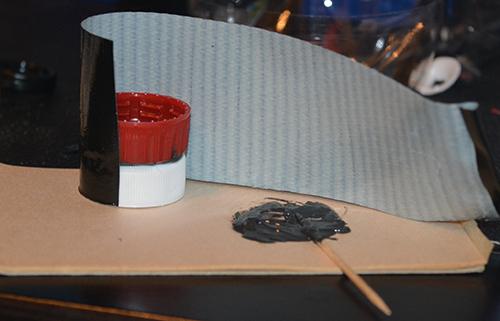

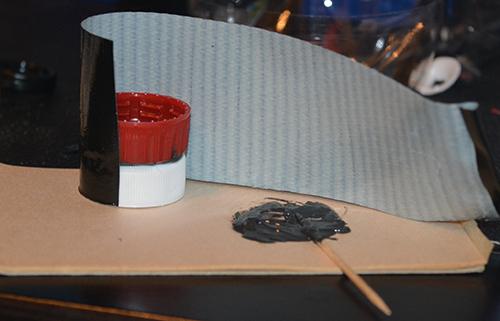

The basic materials consist of:

- 3-liter soda bottle

- 1-liter soda or water bottle

- HEPA filters – such as are used in vacuum cleaners and home air purifiers

- Carbon filter

- Duct tape

- Elastic (not shown)

- Epoxy (not shown)

Building the Mask

I decided that the mask itself had to cover all openings in the face, including the eyes, nose, and mouth. In severely contagious situations, medical personnel wears full-face shields or goggles, so as to protect them from those germ-rich droplets of spittle. If we’re trying to protect ourselves from a pandemic, it only makes sense that we would need to do the same. Hence the 3-liter soda bottle.

I started by emptying the bottles, rinsing them out, removing their labels and drawing the lines where I was going to cut them. The 3-liter bottle is going to be the face mask and the 1-liter bottle the filter.

I’ll connect the two together with a coupling made from the two caps.

There are no exact measurements for the bottles. I found that the width of the opening in the larger bottle, and especially the line of the curve near the top, needs to match the curvature under the chin of the wearer.

What works for me, doesn’t fit right for my wife. For the smaller bottle, I chose the cut line where I did because the bottle narrowed a bit below that point, which would make it harder to install my filter.

Cutting these bottles is easy; it can be done with a hobby or utility knife. However, I found that it was easier to cut them, once I made an initial slit, with a small pair of scissors, something like those used for cutting hair.

The ones I used were serrated slightly, but I don’t think that made any difference.

Later, I decided to use the bottom of the 1-liter soda bottle as well, like a baffle for the filter. So, although there is no line shown in the picture above, I cut the bottom off that bottle and saved it.

Once I cut the outline I wanted in the 3-liter bottle, I taped the edges with duct tape, so as to make it less scratchy. I then punched holes in it with a hole punch and put elastic through the holes to hold the mask to my head.

Building the Coupling

The design concept I have uses two bottles; a large one for the mask and a smaller one for the filter. These two obviously have to be coupled together, in order for the mask to work. Fortunately, the bottle caps made it very easy to create a coupling.

To start with, I needed holes in the caps. Since I had left my drill at my workshop, I grabbed my pocket knife and used that as a drill, to make approximately ½ inch holes in both caps.

Be careful to not use too much pressure on the knife, as you could poke through and cut your hand. The cap material is soft and cuts easily, even when trying to drill through it in this manner.

The two caps need to be glued together for the coupling. For this, I went to my go-to glue, fast-drying epoxy. Epoxy is strong and can be used for just about anything. In this case, the bottle caps are probably polyethylene, which doesn’t glue well.

So I roughed up the surface with some 100-grit sandpaper, giving the epoxy something to grip onto.

To help ensure the strength of the coupling, I then wrapped it in a piece of duct tape, getting a couple of revolutions around the whole coupling. Then I cut the tape flush with the ends of the coupling. If necessary, the duct tape will be strong enough to hold the coupling together, providing an air-tight seal, even if the epoxy is unable to remain bonded to the plastic caps.

Making a Filter

This left me with the need to make a filter. I decided to use a two-stage filter design, for extra security. The first layer, which will be in the smaller bottle, making it replaceable, is a HEPA filter.

The HEPA (high-efficiency particulate absorbing) standard is one that has been developed for air filtration equipment. It must be able to remove 99.97 percent of all particles that are 0.3 microns in size.

Interestingly enough, this specification makes the HEPA filter roughly the equivalent of the N95 mask filter. Actually, I think it’s a bit better; although I won’t guarantee it, as the specifications are written in such a way that it’s a little like comparing apples and oranges.

The language just isn’t the same in the two specifications.

Nevertheless, a HEPA filter is supposed to be able to remove most bacteria and viruses, in addition to particulate matter, so it’s ideal for our purposes.

The HEPA filters I bought are actually designed for use in a home air cleaning system. I could have just as easily used one for a vacuum cleaner, but these were readily available and reasonably priced. By buying them online, I saved myself a trip to the store.

As you can see from the photo above, the filter itself is accordion folded and placed in a plastic housing that holds it that way. As the housing doesn’t match the shape that I need, I just removed the filter medium itself and cut off a section the right size to fit in my bottle. Let me stress – you can do this with any HEPA filter you can find; you don’t need the same filter that I used.

To make my filter unit, all I did was to hot melt glue that accordion-folded filter into the 1-liter bottle. That was actually a bit tricky, as it was hard to get the glue gun down into the bottle to work.

But it is essential that the filter is glued all the way around and that there not be any gaps where air can flow through, without flowing through the filter. You’re better off using too much glue, than not enough.

Finally, I took the bottom of the bottle and glued it to the bottom of my filter unit, inverted. It’s hard to see in the picture above, but the arrow is pointing at a gap in the plastic, where the base of the bottle was indented.

There are five of these gaps between the base and the upper part of the bottle, as installed, giving plenty of room for air to get in.

The idea behind installing the base like this is to act as a baffle, keeping droplets of aerosol from coming into the filter unit and hitting the filter medium itself. While it is still possible for droplets to get in, I felt that it was best to make it as difficult as possible, so that my filter would not become clogged from damp spittle.

I added a second layer of filtration, taping a double layer of activated carbon filter into the bottom of the mask, with duct tape. This is a backup to the other filter, should anything get through it.

Activated carbon has been used in a large number of different types of filters designed to capture microscopic pathogens of the type we are trying to protect ourselves from.

Using the Mask

In order to use the mask, the two bottles are screwed together by the coupling. Then your chin is the curve of the cutout in the mask and lifts the mask up to your face, pressing the top of it against your forehead.

Slip the elastic band around your head to hold it in place.

One of the good things about this design is that it allows you to change your filter element as needed. You can make one mask and several filters, changing them as needed.

This should be every eight hours at the most. If the filter seems to be becoming clogged, change it more frequently.

Start now to make sure you are staying prepared.

via: askaprepper

Follow

Follow